System control

Information concept for a production system control room at SKF

Summary

When SKF decided to build a new production system they identified a need for gathering information from the production system in order to operate it effectively. Therefore, a decision was made to gather information and control systems of the production system, secondary users’ computer, screens and tablets and the operators’ mobiles in a control room.

The purpose of this master thesis was to aid SKF in reducing their production system losses through information sharing and control possibilities of the new production system. The goal was to identify which information and control the operators and operational managers needed in the control room to operate the new production system and to present a conceptual visual suggestion of the screen displays in the control room.

Data was gathered through interviews, observations and company visits. The data was then analysed by system mapping, functional tree analysis and hierarchical task analysis. The visual suggestion of the interface was designed with the help of design guidelines. The result was evaluated through reviews with operators and the process development team and a walkthrough of the interface with the operators.

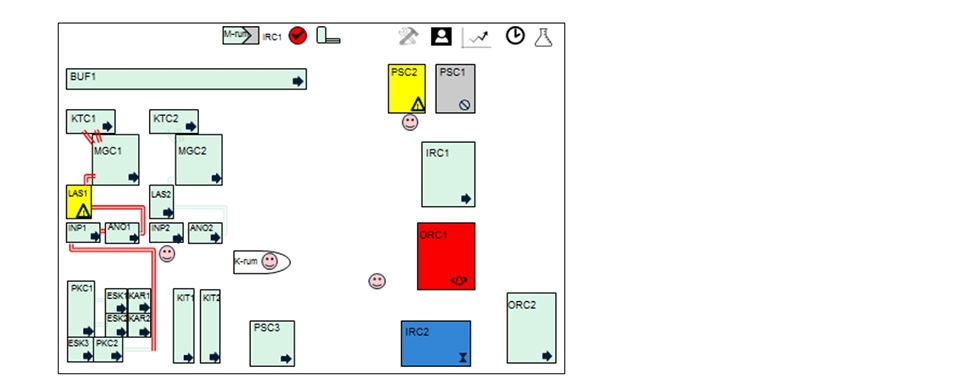

The result of this master thesis shows that the users of the control room need seven main screen displays for the information and control necessary to make decisions in their daily work. The users need a calendar screen for future and past activities in the production system in order to plan their work and make analyses to improve the production system and the work procedures.

The present state of the production system connected to alarm and warning texts but also with possibilities to reach deeper information about the production system was also identified as a requirement. Information about material supply and what they should produce at what time is needed. The need for different communication methods to share information between users was identified. The users also needed prioritizing help for deciding what to do and when. The users need to control the material ordering for the automated guided vehicles, block and order out products from the buffer and order consumables from the control room.

Skriv ut ![]()